#GETTINGBETTERTOGETHER

Our sustainability goals

As part of our integrated sustainability management programme, we are pursuing a number of different goals in the three areas of ecology, economy and social affairs.

Here are some of our sustainability goals.

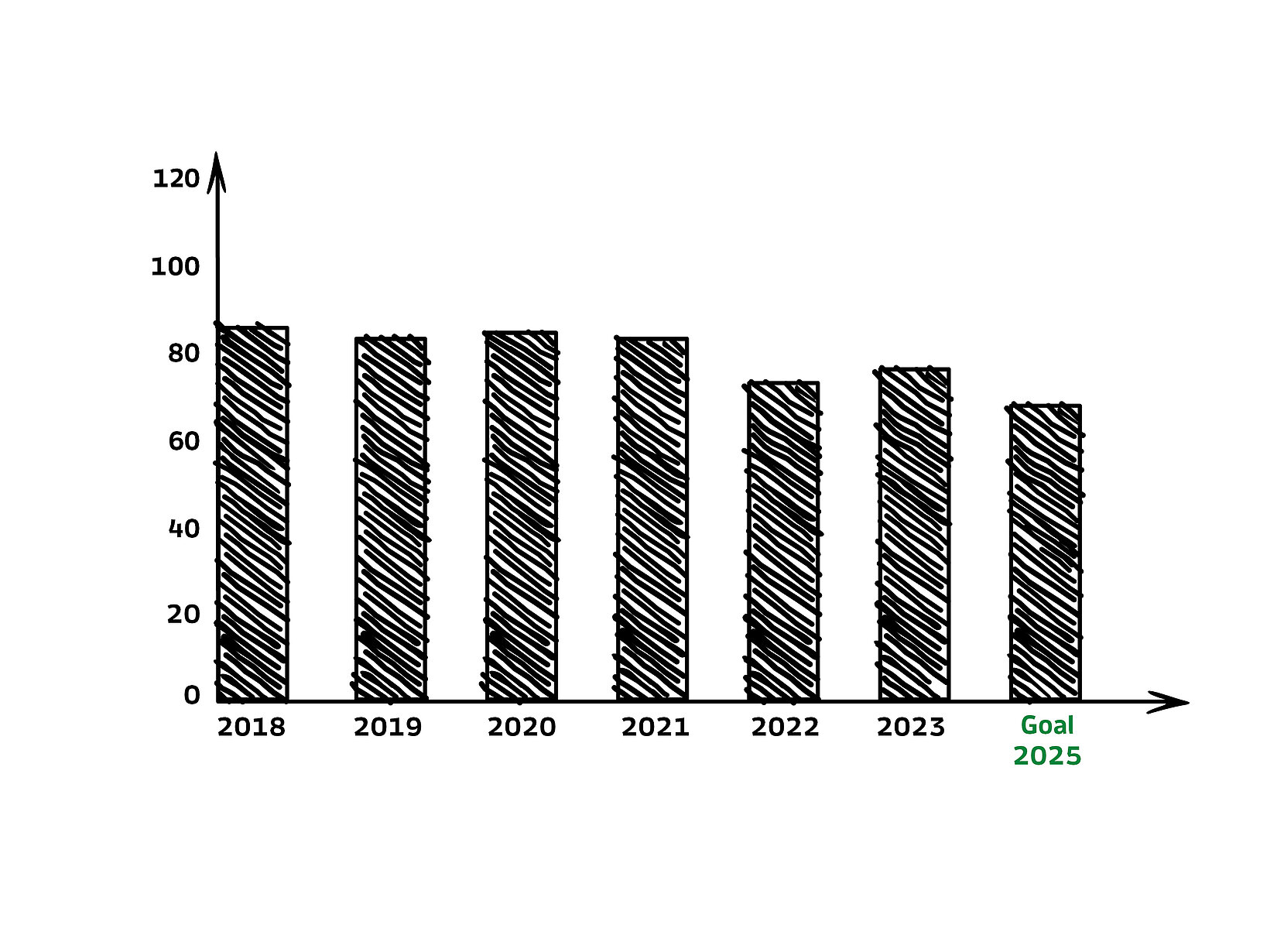

Goal 1

Reduce the total energy consumption for production activities by 23.5 % per ton of finished product by 2025 compared to 2018

Plans for 2025:

- Optimization of refrigeration systems, brine control, and heating networks

- Development of a manufacturing execution system (MES)

- Expansion of control technology (control room & visualization)

- Introduction of AI-supported defrost optimization with Coldsense

- Integration of TCO assessments for investments

- Master's thesis on differentiated analysis of energy consumption per product group

- Launch of decarbonization strategy, including external planners

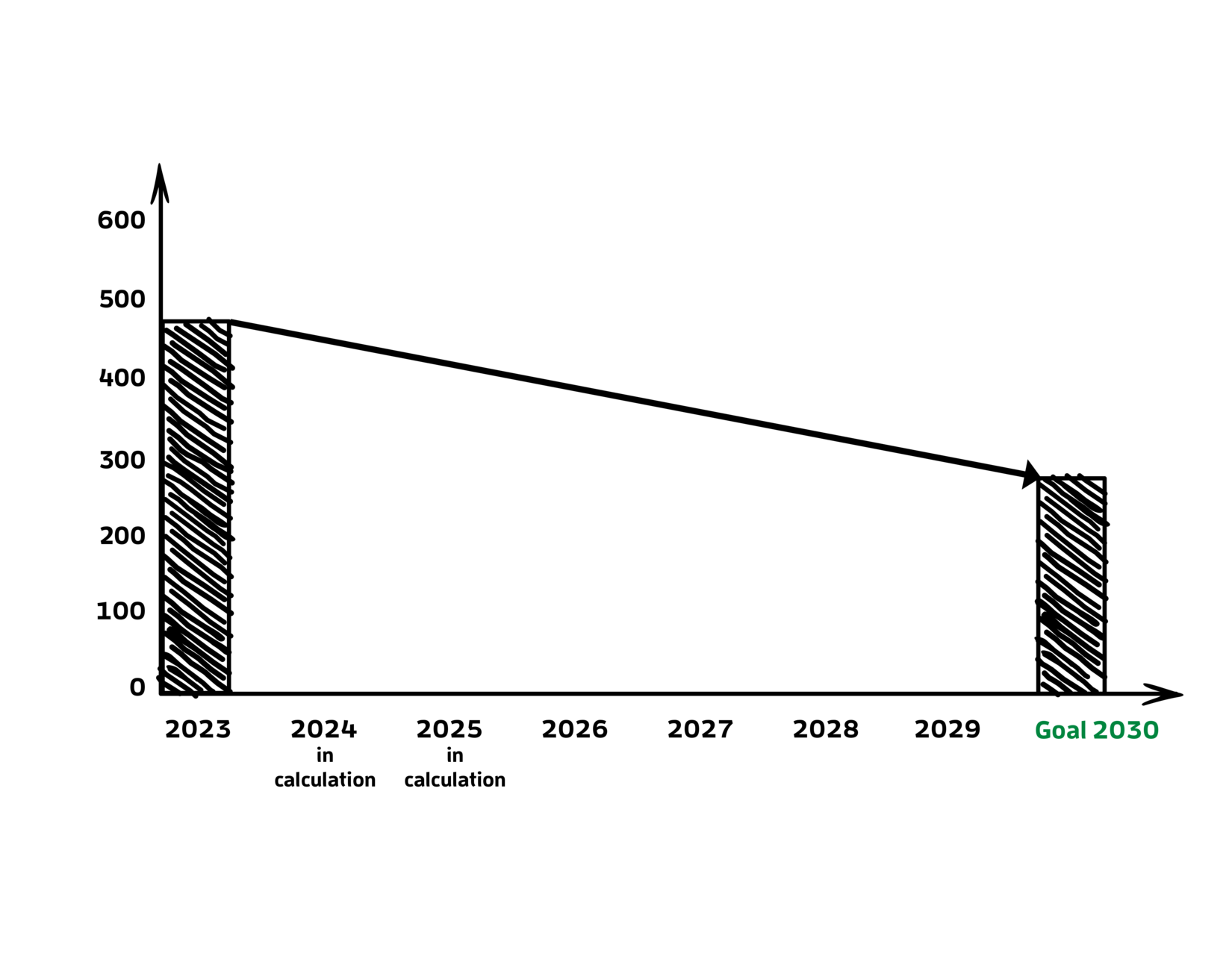

Goal 2

Reduction of Scope 1 GHG emissions by 42 % by 2030 (base year 2023)

Status 2023: 48.922,43 t CO2

Calculations for 2024 and 2025 are in progress.

Plans for 2026:

- Optimization of the defrosting process for evaporators

- Planning and construction of a battery storage facility

- Expansion of the PV carports

- Decarbonization of the vehicle fleet

- Continuous steam trap monitoring

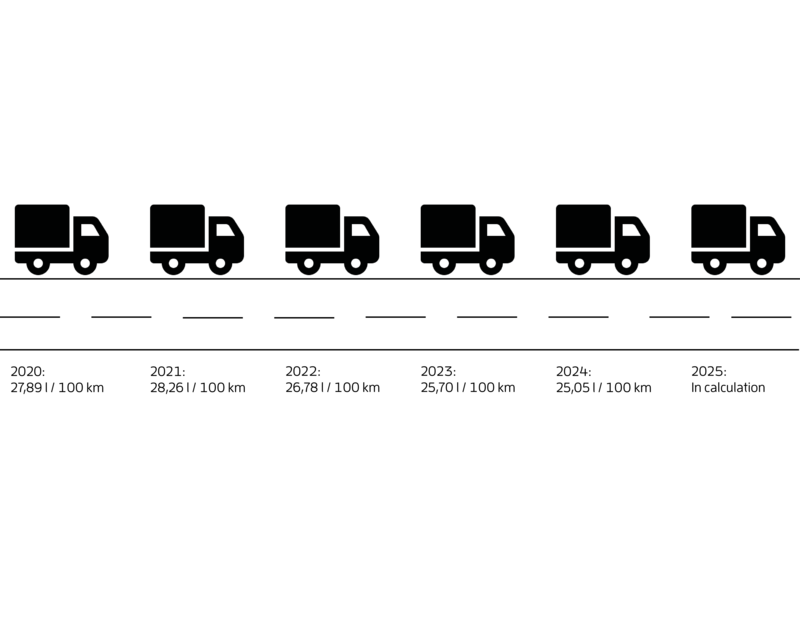

Goal 3

Reduce or maintain average fuel consumption for the long-distance fleet to below 26.5 l/100 km by 2030

The long-distance fleet is continuously renewed. The fleet is monitored by a modern Fleetboard system (telematics system) with the following objectives.

Plans for 2026:

- Commissioning of the first two electric trucks

- Commissioning of fast charging stations for trucks

- Expansion of our own charging infrastructure

- Continuous fleet modernization

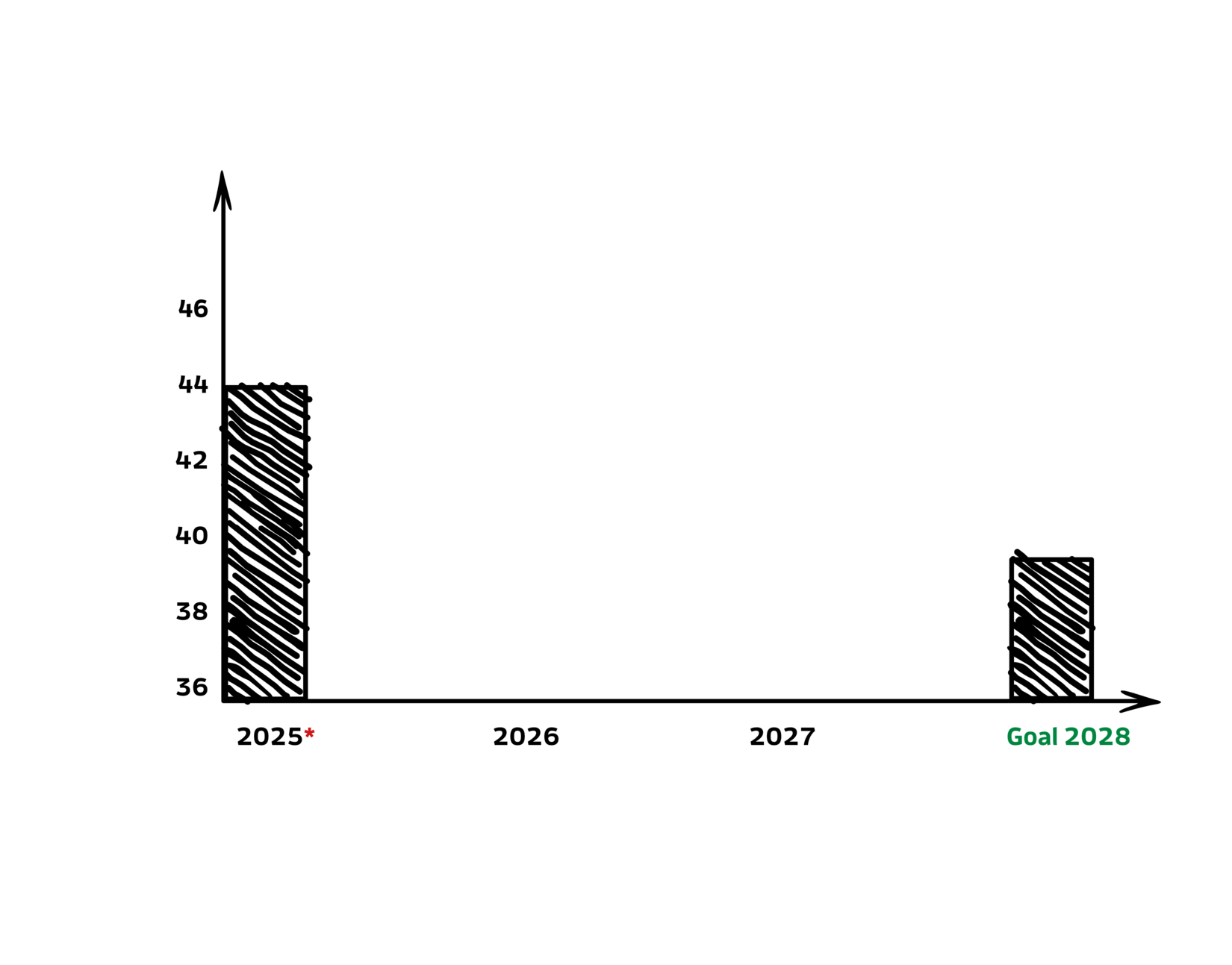

Goal 4

Reduction in the workplace accident rate (per 1,000 full-time employees) by 10 % by 2028 compared to the base year 2025

* provisional value

Plans for 2026:

- The integration of occupational safety on the shop floor will be introduced in other departments

- Further tests and trials with an EXO skeleton will be carried out to improve the technology for heavy physical work

- All managers are to take part in training on the topic of “Responsibility in occupational safety”

Goal 5

By 2030, at least 7 % of the workforce at the Addrup site should be trainees (m/f/d) each year

Status in 2025: 92 trainees = 6.6 %

Plans for 2026:

- Participation in career fairs and information events at schools to directly address potential trainees

- Recruiting via Instagram with authentic insights into everyday training life

- Training and further education for trainers and training officers